FAQs

How does Air Conditioning work?

A fridge or freezer is an appliance that removes heat from one area (where food products are stored) and discharges this unwanted heat to another area (usually into the surrounding air at the back of the appliance).

The “refrigeration circuit” consists of a freezer section that has very cold refrigerant gas passing through it, a compressor (that’s the big black metal thing near the floor at the back) that drives the refrigerant through the pipes, and a condenser (a series of tubes at the back, which are quite warm to touch). The condenser tubes are actually discharging unwanted heat into the surrounding air.

An air conditioning system is a larger version of the fridge/freezer, which removes heat from one area (a room inside the building) and discharges it through its condenser to outside the building.

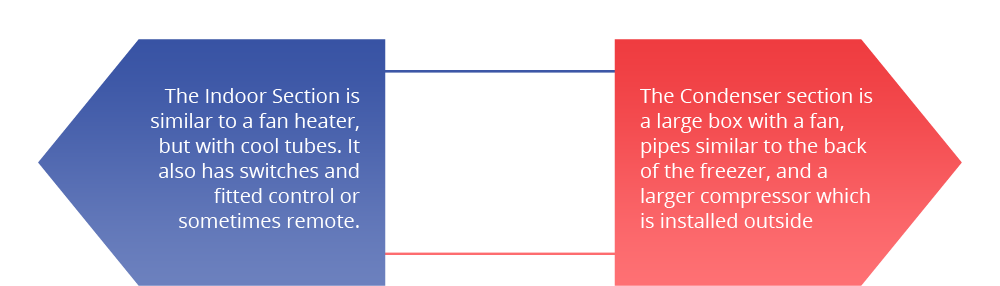

In order to make it practical to install an air conditioning system in a building, the “refrigerant circuit” of an air conditioner is divided into two parts; joined by a pair of small diameter copper pipes.

The indoor units come in all shapes and sizes, some designed to fit on a wall, or ceiling and some hidden above a ceiling with air ducts connected, also some half in / half out of the ceiling.

The indoor unit and the outdoor unit (which includes the compressor) are powered by electricity. As a guide, an air conditioner that has a cooling performance of 6kw will consume about 2Kw of electricity when operating continuously.

What is a heat pump?

A heat pump system, like an air comfort cooling system, has an indoor unit/interconnecting pipes/outdoor unit, but it also has a reversing valve which pumps the refrigerant the other way around the circuit. This “reverse cycle” operation makes the outdoor unit cool the surrounding air and the indoor unit discharges its heat into the room.

Heat pumps are an integral part of air conditioning technology. Heat pumps transfer heat from one environment to another via refrigerant. In cooling mode, heat pumps transfer the heat in an enclosed area (room, industrial process) to the outside air, resulting in a cooling of the area in question. This is the role that heat pumps play in common refrigeration and air conditioning systems. Heat pumps, however, also allow this process to be reversed. They can pump heat extracted from the outside air indoors, allowing indoor environments to be heated as well as cooled using the same technology.

Why is heat pump Air conditioning so energy efficient?

Heat pumps offer numerous advantages as a heating solution. The same systems used to cool can also be used to heat, resulting in less initial investment and simplicity in operation and maintenance. Heat pumps also have an important advantage in the area of efficiency. Unlike fossil-fuel based heating systems, heat pumps extract available heat from the outside air.

Heat pumps offer efficiency gains on the order of 3:1 and higher, compared to electrical heating. Thus for every unit of energy consumed by the heat pump, three or more units of heat are gained.

Can Heat Pumps supply hot water?

Yes, using the same process as above, but instead of transferring the heat into air it is transferred in to water. Hot water can be supplied for sinks and showers as well as for radiators and/or underfloor heating purposes.

How often will filters require cleaning?

All manufacturers’ recommend that filters are cleaned or at least checked once a month, however this depends on the application and level of usage. For example, filters in a home with pets will need cleaning more frequently than in a home without pets.

However, commercial and industrial installations vary widely according to the type of business, for example an office will not require filters to be cleaned as much as a shop with a high volume of traffic and doors to outside, opening and closing.

How often will the system need to be serviced?

Manufacturers’ recommend that systems be serviced ‘regularly’ which again will depend on the factors mentioned above (See “How Often Will Filters Require Cleaning”).

However with domestic heat pumps we would suggest that the systems are serviced on ‘changeover’ from cooling to heating and possibly vice-versa. Systems installed within commercial and industrial surroundings we would recommend 3 or 4 service visits per year, but any servicing would need to be specifically tailored to the installation.

Klima are pleased to provide a free of charge quote with no obligation tailored to meet your requirements.

What certification is required by law for a Refrigerant / Air Conditioning contractor and why?

Any person installing equipment containing refrigerant is now required by law to be registered with Refcom and have F-Gas certification in respect of safe handling of refrigerants. This is a direct response to reducing CFC emissions to combat environmental issues. All of Klima Solutions engineers take part in regular training to ensure we are compliant and knowledgeable within all aspects of the air conditioning industry and current Health and Safety regulations.

Considerations during a Site Survey

There are many different and varied considerations to be taken into account when carrying out the initial site survey. We have listed some of the main points overleaf.

-

What are the end users primary requirements (cooling, heating or a combination of both)?

-

Where is it required (bar, meeting room, office etc)?

-

What are the dimensions of the area (height, width, depth, a sketch is always useful)?

-

What is the building made from (wood, brick, concrete etc)?

-

Is there any external glazing in the space (are there any windows, how many, double glazed)?

-

How many people will use the space at peak times (and what are the peak times)?

-

Is there any equipment in the space (computers, speakers, fridges etc)?

-

What is the best type of internal unit for the space (taking into account the height, width and length)?

-

Is there sufficient space for the internal unit you require (for example a cassette unit will require a ceiling void height of approximately 320 mm)? If there is not sufficient room you will need to change the type of internal unit.

-

Where can the external unit go (remembering the points detailed above)?

-

Where and how will the interconnecting pipework run between the internal and external units (can it run through a ceiling void straight through a wall to the external unit for example)?

-

How long is the pipework run (approx) between the internal and external units? Most systems have a maximum run of 50 metres; if the run is over that length think again.

-

What sort of electrical power does the building have and does it have sufficient capacity left for the required units on an existing distribution board (most systems will require a single phase 25 or 32 amp supply)?

-

What degree of building work is required (for example is it just modifications to ceilings or do whole sections need to be removed)?

Refrigerant pipework is very similar to the pipework used in your central heating systems. If you feel this sort of pipework could be installed relatively easily then the chances are refrigerant pipework can be installed to.

Klima are pleased to provide a free of charge quote with no obligation tailored to meet your requirements.

What is the procedure and how long will the installation take?

There are many different and varied systems available where a single outdoor unit can be connected to several indoor units but for this purpose we have based the below information on a single split system (one outdoor unit connected to one indoor unit).

-

Outdoor unit to be placed in position either on brackets on a wall or at ground or roof level.

-

Indoor unit support work to be positioned in previously agreed locations.

-

Holes to be drilled to allow pipework to be routed between the units.

-

Suitably insulated refrigerant quality interconnecting pipework, generally comprising 2 pipes, to be run between the outdoor and indoor units (refrigerant quality pipework must be used to cope with high pressure refrigerant, plumbers copper would be dangerous).

-

Interconnecting cabling to be run between the indoor and outdoor units.

-

Indoor unit to be fixed into position with a drain line run to ensure effective discharge of condensate for which a pump may be required.

-

Outdoor and indoor units to be connected electrically and mechanically to the pipework and cabling.

-

Controller to be located in a convenient position adjacent to the indoor unit with control cabling run as necessary back to the indoor unit.

-

Interconnecting pipework to be pressure tested to ensure pipework integrity.

-

Following successful evacuation and dehydration, a specific / critical amount of refrigerant is to be charged into the system.

-

System to be run, tested in all modes (cooling, heating, dehumidification and fan only) and commissioned.

-

Our engineer will then run through the controls and system operation with the end user.

-

Commissioning information will be sent to the client as a matter of routine once the system has been demonstrated to the end user.

What is a VRF / VRV system?

VRF stands for Variable Refrigerant Flow / VRV stands for Variable Refrigerant Volume (same thing, different wording) and these systems provide very energy efficient heating or cooling.

The system gets inputs from the user (e.g. desired comfort temperature) and from the surroundings (outside ambient temperature), and according to that data it adjusts the flow of the refrigerant in order to get to the desired comfort conditions, utilizing optimal power consumptions.

Being able to adjust itself to outdoor conditions is one of the main factors that makes VRF systems so efficient, compared to the traditional water cooled systems, based on chillers and fan coils.

A VRF / VRV system involves a single large outdoor unit connected to several indoor units;

-

A heat pump VRF / VRV system will require that all the indoor units are either cooling or heating

-

A heat recovery VRF / VRV system can provide simultaneous heating and cooling, i.e. some indoor units can be cooling whilst others are heating.

A heat pump VRF / VRV system is very energy efficient; the heat recovery VRF / VRV system takes this energy efficiency even further by transferring heat across the system. For example, if a building receives the sun on one side only in the morning the heat from the units on the “warm” side of the building can be transferred to the units on the “shady” side.

The energy efficiency can be even further improved by including a heat pump boiler within the system so that any rejected heat can be recovered into the hot water system to reduce conventional boiler running costs.

The above is a very brief guide to these systems, and we would be pleased to discuss any aspect in depth without obligation.

What is a Heat Pump Boiler?

Generally the heat pump boiler is a heat pump that will recover heat and discharge it into water for either underfloor heating, low temperature radiator/fan coil heating or hot water purposes. See also ‘What is a Heat Pump?’

How can Heat Recovery Ventilation Units improve energy efficiency even more?

These HRV units provide fresh air and also extract ‘stale’ air, however heat is recovered between the fresh air and exhausted air, without mixing, to pre-heat or pre-cool incoming air. This means that ‘paid for’ heating or cooling is not extracted with the exhaust air and that further energy is not required to heat and cool the incoming air. These units will also recover / reject heat from / to ambient air to provide ‘free’ heating or cooling.

These units can either work independently or be linked into air conditioning controls so that they work in tandem with each other; for example if there is sufficient heating or cooling from ambient air the AC controls will detect this and adjust the cooling or heating output accordingly.

If there are any subjects that are still unclear please feel free to contact Klima Solutions using the contact form.

Klima Solutions, for complete Air Conditioning Solutions. Design, Installation and Service.

Klima House

Blacknest Industrial Estate

Blacknest

Hampshire

GU34 4PX

Phone: 01420 520835

|